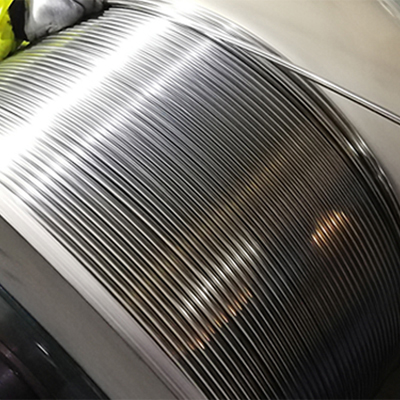

Songyang Baofeng Precision Clean Tube Co., Ltd. is a professional enterprise dedicated to the research and production of stainless steel and special alloy steel ultra long coil tubes. Jointly funded by Baofeng Steel Industry Group and Zhejiang Jingning Clean Steel Pipe Co., Ltd. The production plant covers an area of over 30000 square meters, with over 220 employees and a total investment of 150 million yuan. It has built four world-class stainless steel ultra long seamless coil dedicated production lines. The production process adopts: hot extrusion/side hole+cold rolling+cold drawing+bright vacuum solid solution heat treatment. The annual output of stainless steel seamless coil is 12000 tons, providing safe and reliable products for oil, natural gas, power, semiconductor, nuclear power, chemical industry, shipbuilding, new energy and other fields. The production and sales of coil tubes rank among the top in the country.

Latin: ASTM A213 ASTM A312 ASTM A269ASTMM A270