Product Introduction

Quality Management

production equipment

The company is equipped with facilities such as cold rolling tube mill, bright heat treatment furnace, first developed cold drawing tube machine, self-developed flat automatic coil degreasing and cleaning equipment, vacuum heat treatment furnace, water pressure testing device, etc. It has advanced and complete processes, production lines, and production conditions. By adopting new technologies, processes, and equipment, efforts have been made to enhance high-quality products with high technological content and high quality requirements.

test equipment

- Component analysis :Full element analysis of photoelectric direct reading spectroscopy

- Metallographic Test :High magnification inspection, low magnification inspection

- Mechanical performance test :Room temperature tensile test, intergranular corrosion test, hardness test

- Process performance test :Expansion test, flattening test, flattening test, curling test, bending test Verification and water pressure test

- Non destructive testing :Ultrasonic testing and eddy current testing

- pre-sale Pre sales service - using high-quality domestic raw materials to ensure material safety; Provide technical consulting services

- In sales service。 一一 During the production process, each process is strictly controlled, and all data is monitored and analyzed in real-time through specialized management software for the steel pipe industry To ensure the quality of the steel camp more effectively; The company's stainless steel pipe technology research and development center can provide customized services for users Special requirements for product improvement or re research发

- after-sale service 一一Based on user feedback, continuously improve product quality to meet user requirements

Assembly line production system

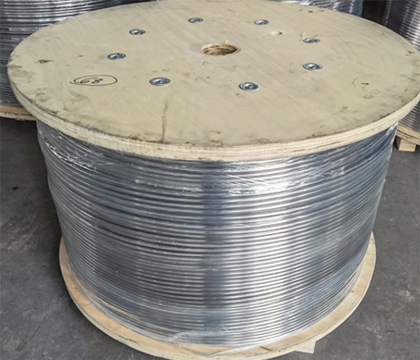

Baofeng Precision has built four world-class production lines for special seamless coils (hot extrusion/piercing+cold rolling+cold drawing+bright vacuum solution heat treatment), a complete quality management system, and accurate detection instruments to provide safe and reliable products for oil, natural gas power, semiconductor, nuclear power, chemicals, shipbuilding, new energy and other fields. The production and sales of coil tubes rank among the top in China.

Over the past 22 years, the R&D department has independently developed multiple patented products and technologies, thus embarking on a new path of upgrading traditional industries through high-tech transformation. Taking the transformation of industrial high-tech into high-tech output of high-quality products as the research and development goal, providing a solid guarantee for products to win the market.